Increase Efficiency: Exactly How Updating Undercarriage Parts Can Improve Effectiveness

Increase Efficiency: Exactly How Updating Undercarriage Parts Can Improve Effectiveness

Blog Article

Maximize Efficiency With Resilient Undercarriage Components

In the world of heavy equipment and devices, the role of undercarriage components is critical in ensuring optimum performance and durability. The efficiency and efficiency of these components can considerably affect the overall procedure of machinery, making the option of long lasting undercarriage parts a crucial decision for supervisors and operators alike. By discovering the elaborate partnership between longevity and performance in undercarriage components, a deeper understanding of the subject emerges, clarifying the critical variables that drive operational success. As we navigate via the complexities of undercarriage durability, part, and upkeep selection, a detailed expedition waits for to unveil the crucial approaches for achieving peak performance in durable applications.

Benefits of Utilizing Resilient Undercarriage Parts

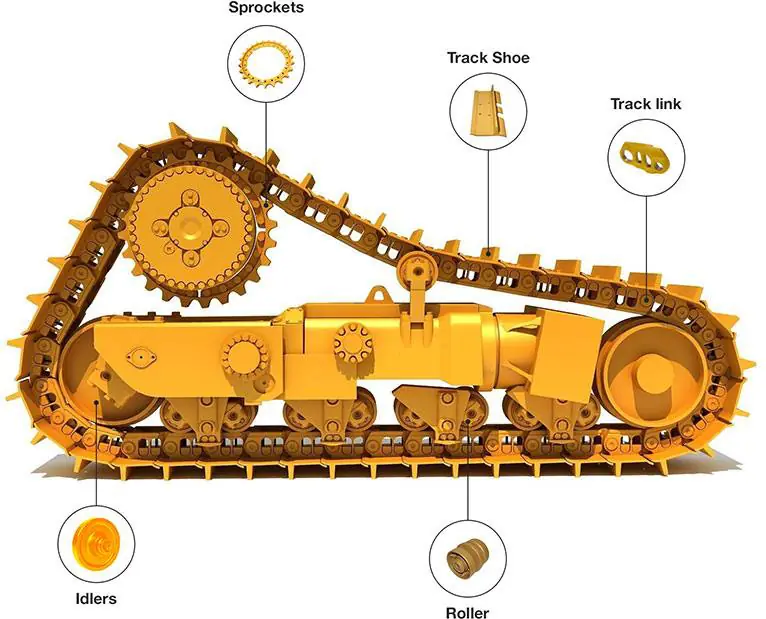

Using long lasting undercarriage components not only improves the durability of heavy machinery but also reduces maintenance costs considerably. By investing in premium undercarriage elements, such as tracks, idlers, gears, and rollers, devices operators can experience enhanced uptime and improved overall efficiency.

Moreover, the durability of hefty equipment is directly linked to the top quality of its undercarriage components. Durable elements can hold up against the rigors of demanding applications, making sure that the tools remains operational for prolonged durations. Because of this, operators can avoid expensive downtime and upkeep expenditures, inevitably taking full advantage of the roi for their equipment.

Factors Impacting Undercarriage Toughness

The longevity of undercarriage components in heavy machinery is affected by different vital elements that straight influence performance and longevity. High-grade products, such as hardened steel, are essential for holding up against the severe conditions and hefty loads that undercarriage components are subjected to - undercarriage parts.

Additionally, environmental variables can have a considerable influence on the long life of undercarriage components. Direct exposure to rough products, extreme temperatures, and extreme working problems can increase damage on undercarriage components. Picking undercarriage parts that are particularly designed to stand up to these ecological challenges is crucial for ensuring toughness.

In addition, the design and engineering of undercarriage parts have a straight impact on their durability. Parts that are made to distribute loads uniformly, minimize rubbing, and decrease stress concentrations are more probable to have a much longer life-span - undercarriage parts. By taking into consideration these crucial elements, devices drivers can maximize the resilience and performance of their undercarriage elements

Maintenance Tips for Prolonging Undercarriage Life

Executing routine maintenance routines is important for prolonging the life expectancy of undercarriage elements in heavy machinery. To prolong the undercarriage life, it is crucial to frequently inspect for wear and tear. Regularly check for loosened or absent bolts, harmed rollers, or misaligned tracks, as these concerns can rise and trigger additional damage otherwise resolved without delay. Furthermore, make sure that the undercarriage is correctly lubricated according to manufacturer standards to minimize friction and prevent early wear.

One more vital upkeep tip is to maintain the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can speed up wear and corrosion, causing costly fixings. Washing the undercarriage after procedure in harsh problems is recommended to stop these problems.

Last but not least, tracking and recording upkeep tasks can assist in developing a positive upkeep routine. Keeping thorough records of examinations, repair services, and substitutes can give important insights right into the undercarriage's problem and performance in time, helping in forecasting and preventing prospective failures. By adhering to these upkeep tips vigilantly, operators can dramatically increase the resilience and performance of undercarriage components in hefty equipment.

Picking the Right Undercarriage Elements

Selecting appropriate undercarriage components is important for making best use of the efficiency and longevity of heavy machinery. There are a number of elements to think about when it comes to choosing the best undercarriage components. One key factor is understanding the specific requirements of the equipment and the setting in which it will certainly operate. Different applications may ask for various kinds of undercarriage elements, such as tracks, rollers, idlers, and sprockets. It is important to choose components that are designed to withstand the certain problems the device will run into, whether it be harsh terrain, unpleasant products, or extreme temperature levels.

Opting for respectable brand names known for producing high-performance and sturdy undercarriage components can significantly impact the general efficiency and long life of the equipment. By meticulously selecting the best undercarriage elements, devices proprietors can boost performance, lower downtime, and expand the life-span of their hefty equipment.

Case Researches: Enhanced Performance With Durable Components

Incorporating long lasting undercarriage parts has shown significant improvements in machinery performance. One instance study included a building and construction company that updated its excavator's undercarriage components to much more sturdy options.

In one more circumstances, a mining operation changed the undercarriage components of visit here its bulldozer with top notch, sturdy alternatives. This button brought about an amazing enhancement in the excavator's ability to move and overall performance. The maker can navigate challenging terrains a lot more successfully, leading to enhanced operational effectiveness and lowered gas consumption.

Additionally, a logging business spent in sturdy undercarriage components for its forestry tools. The upgraded components exhibited prolonged lifespan and enhanced resistance to abrasion from rough terrain. The company experienced reduced maintenance prices and better tools uptime, inevitably website here enhancing its lower line. These instance researches underscore the concrete advantages of using long lasting undercarriage parts in enhancing equipment efficiency and durability.

Verdict

In conclusion, using sturdy undercarriage parts can dramatically improve efficiency and longevity of heavy visit homepage equipment. Case research studies have actually shown that spending in sturdy undercarriage parts can lead to enhanced total performance and performance in various markets.

The performance and effectiveness of these components can substantially affect the overall operation of equipment, making the option of durable undercarriage parts a vital decision for supervisors and drivers alike.Including durable undercarriage parts has shown substantial improvements in machinery performance. These case research studies highlight the substantial advantages of making use of durable undercarriage parts in optimizing machinery performance and durability.

In final thought, using long lasting undercarriage components can dramatically boost efficiency and long life of hefty equipment (undercarriage parts). Instance researches have actually revealed that spending in sturdy undercarriage components can lead to boosted total efficiency and efficiency in different markets

Report this page